Applications

Exotic materials machining

Overview

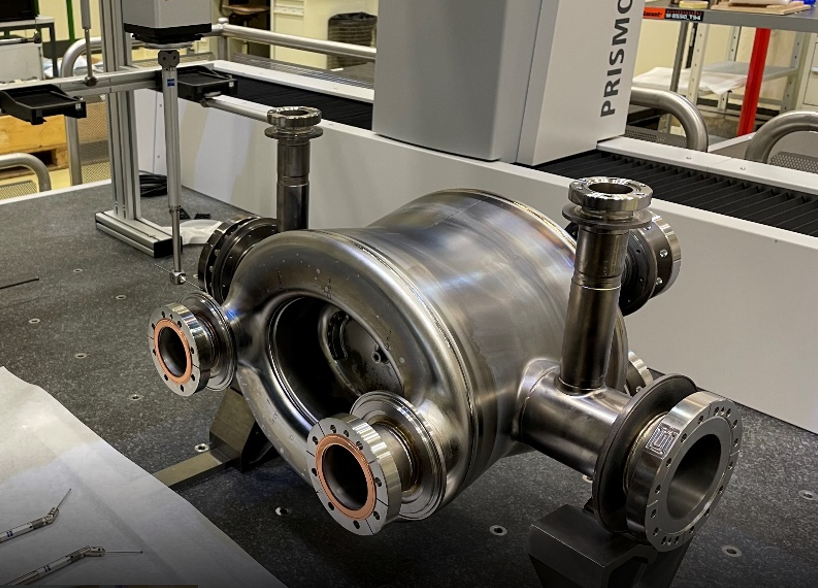

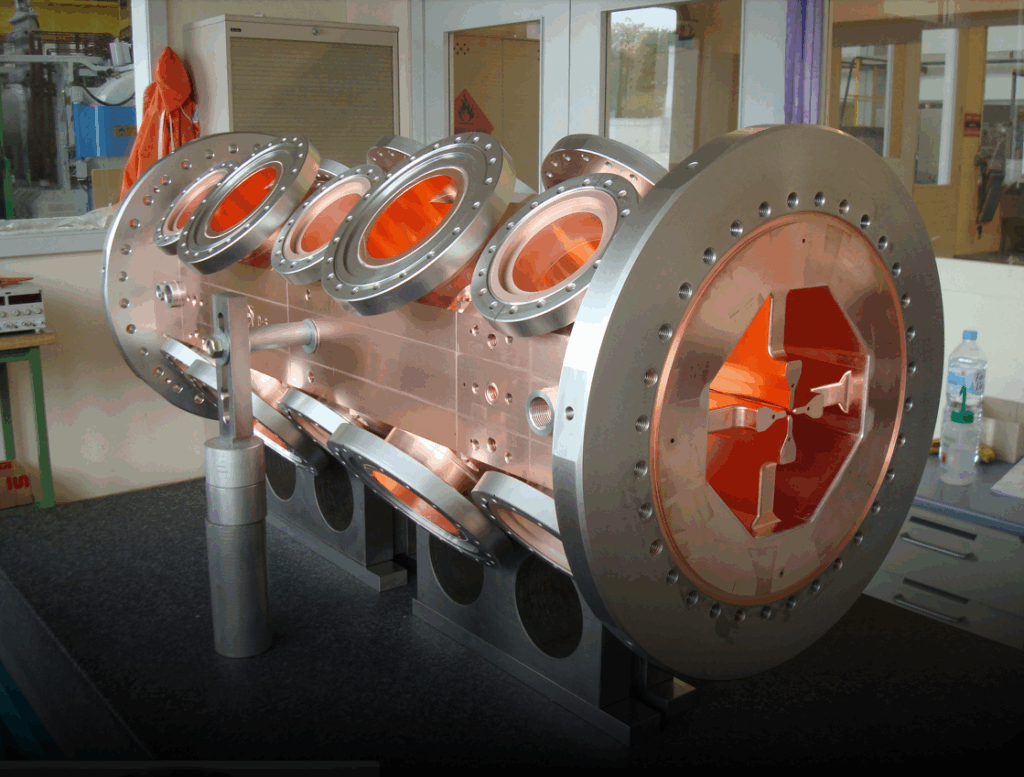

Our workshop has strong expertise in machining exotic materials chosen for their unique properties, enabling them to meet the demanding requirements of accelerator physics and withstand extreme conditions. These requirements include compatibility with ultra-high vacuum, minimal interaction with particle beams, and resistance to radiation damage. This specialized knowledge allows us to manufacture, maintain, and adapt equipment that supports scientific discovery at the highest level.

Exotic Materials

Among the various exotic materials we work with, we produce high-precision components in niobium and its specialized alloys, as well as in pure oxygen-free copper (OFE), and beryllium, ensuring exceptional quality and performance for demanding applications across multiple advanced industries.

Know-how

Exotic materials present machining challenges. Over the years, we have developed our expertise through both hands-on experience, targeted R&D, and close collaboration with academia and metallurgy specialists from our group. Our work includes quantifying the effects of cooling fluids, optimising cutting conditions and tool parameters, and ensuring compatibility with the specific requirements of CERN’s accelerators, detectors, and experiments.

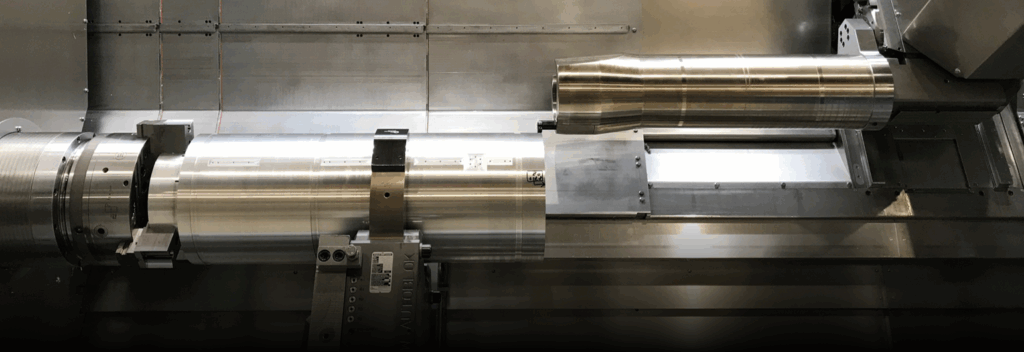

Ultra-precision machining

Precision where it matters most

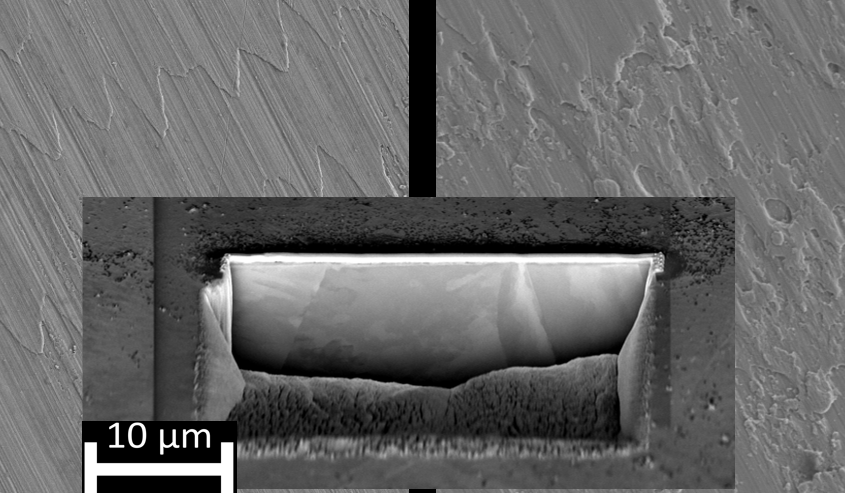

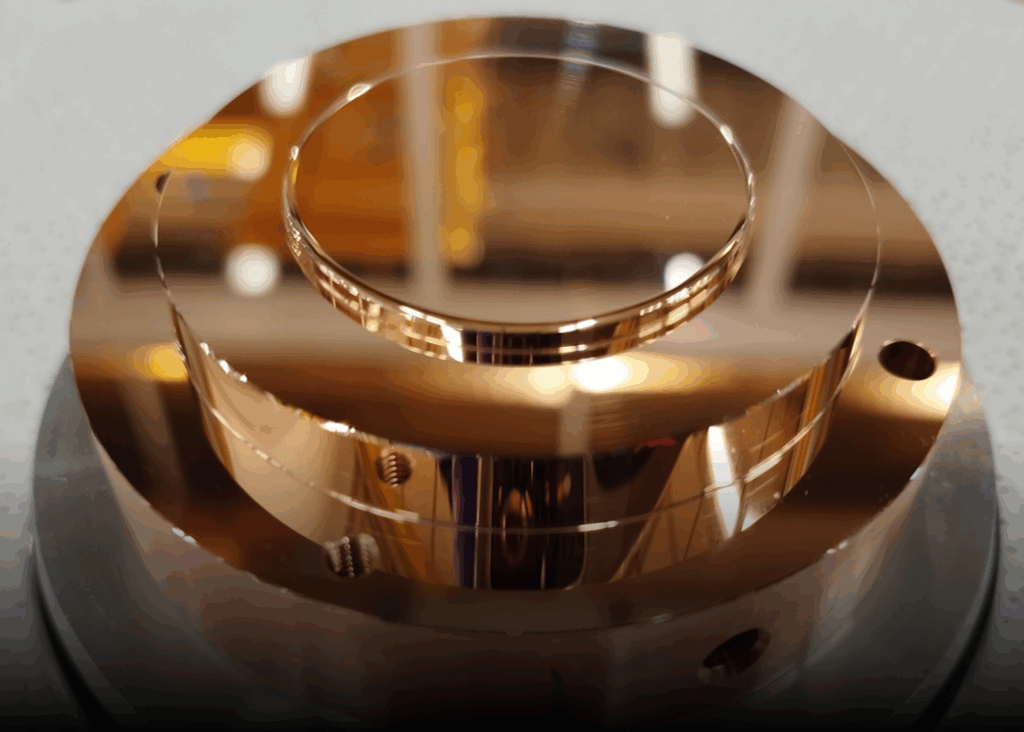

CERN’s ultra‑precision turning capability enables shape tolerances within just a few microns. This level of precision plays a vital role in producing components for advanced accelerator structures.

Surface finishes tailored for performance

Our processes enable exceptionally smooth surfaces, reaching nanometer-level roughness. Such finishes are essential for certain components interacting with particle beams or operate under high-frequency electromagnetic fields, where surface quality directly affects performance.

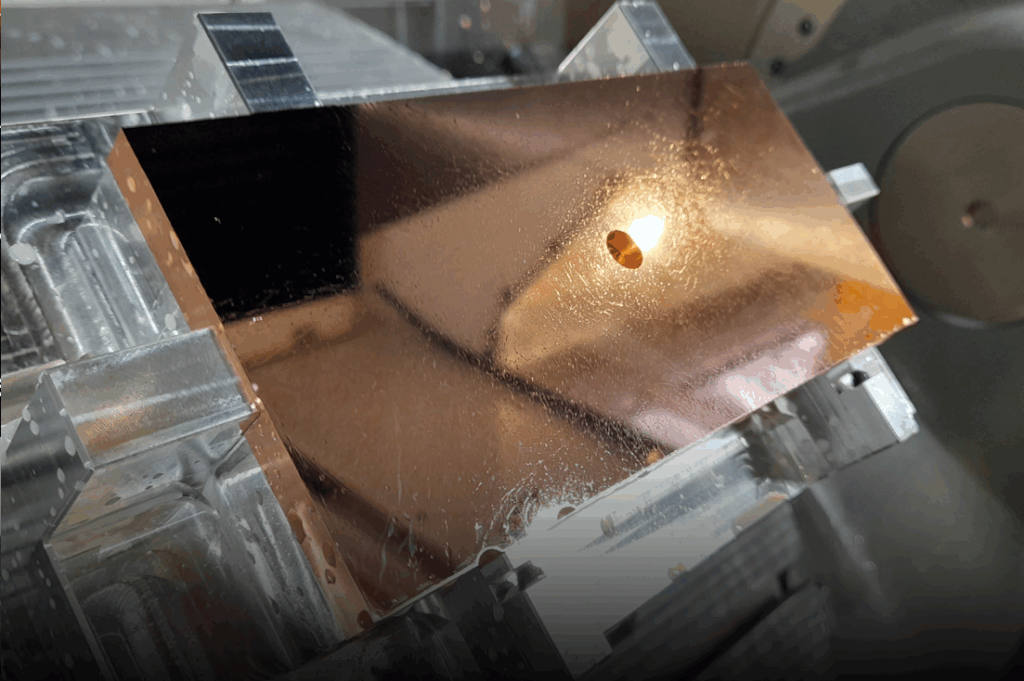

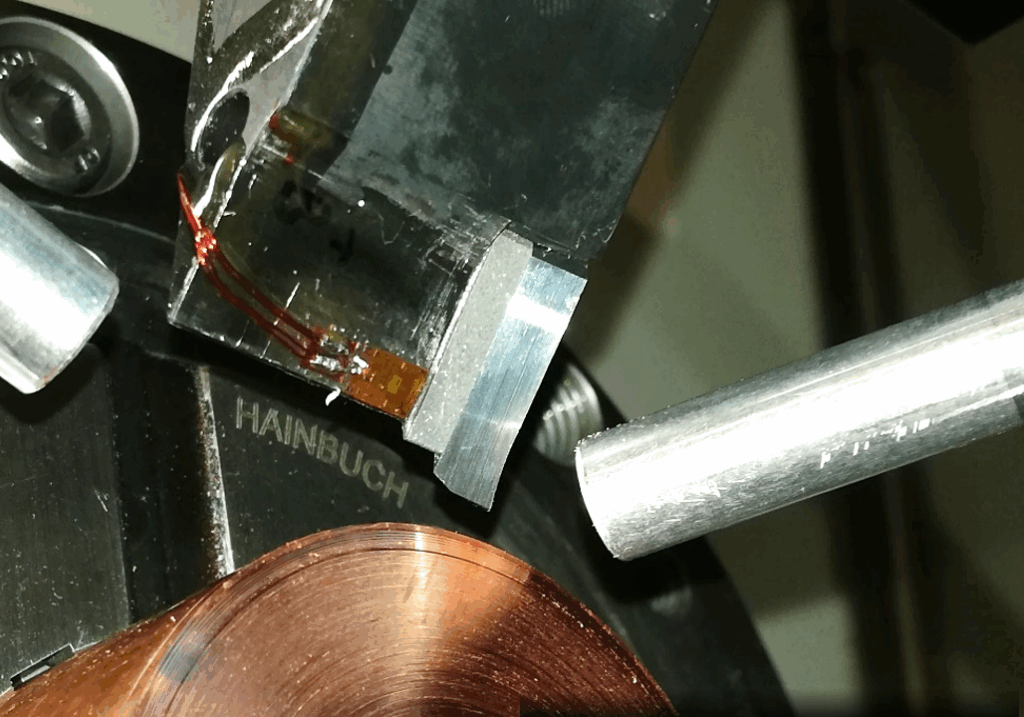

Cryogenic machining

What is it?

Cryogenic machining is an advanced manufacturing technique where extremely cold media are applied directly into the cutting zone during turning or milling. Unlike conventional oil-based coolants, cryogenic coolants evaporate completely, leaving no residues on the machined surface, ensuring cleaner parts and reducing post-processing requirements. This technique also enhances tool life, surface quality, and dimensional stability in precision applications.

Component manufacturing

The approach of residue-free manufacturing of UHV and RF applications is studied at CERN to address two long-standing challenges in accelerator component manufacturing:

- Cleanliness: This emphasises on avoiding contamination of components that must operate in ultra-high vacuum (UHV) or sensitive environments.

- Surface Integrity: This enables minimizing roughness and microstructural damage. This makes it a cleaner, more sustainable alternative to traditional cutting fluids.

Lightly radioactive components machining

Overview

Some of the components we handle at CERN become slightly radioactive during operation. These activated parts are essential for experiments and require specialised handling when they need to be maintained, repaired, or adapted. Our workshop is equipped to machine such components under strict safety standards, ensuring both the protection of staff and the precision of the work.

Expertise

Radioactive machining demands an additional layer of know-how. Over the years, we have developed methods to address the specific constraints of mildly radioactive components while ensuring safety aspects. We rely on dedicated machines and facilities specifically designed for this purpose. Every intervention is performed with full traceability and in close collaboration with the radioprotection group, who oversees the safety of the whole procedure.

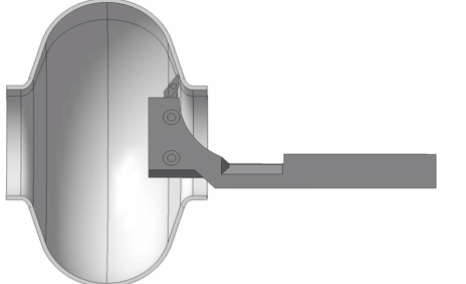

Process engineering and design

Bespoke tooling to advance science

Our bespoke tooling design approach enables the machining of complex, hard-to-reach geometries, making it possible to produce seamless prototypes with exceptional accuracy and repeatability. This approach secures precision on complex accelerator components.

Fixtures to secure quality

Well-designed fixtures don’t just hold a workpiece, they are the silent partners in precision manufacturing. Our fixture designs are tailored to each part, ensuring perfect positioning and absolute stability throughout the machining process. They allow us to securely hold even components with highly complex geometries, enabling machining that would otherwise be impossible.

Key aspects include:

- Custom clamping solutions that prevent distortion, even with delicate parts.

- Full accessibility for multi-axis machining, reducing setups and improving accuracy and efficiency. Integration with metrology.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the MME Machining Workshop can do for you.