Machining

Meeting accelerator requirements with high-precision manufacturing

Turning ideas into science-ready solutions

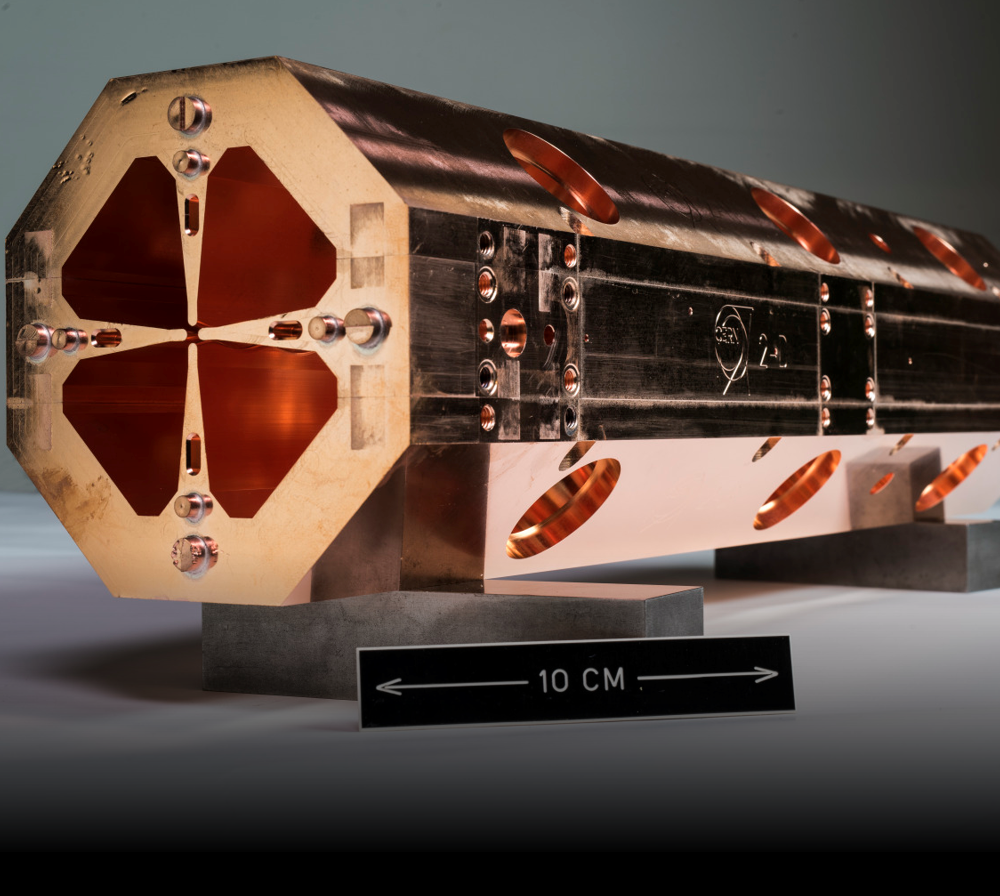

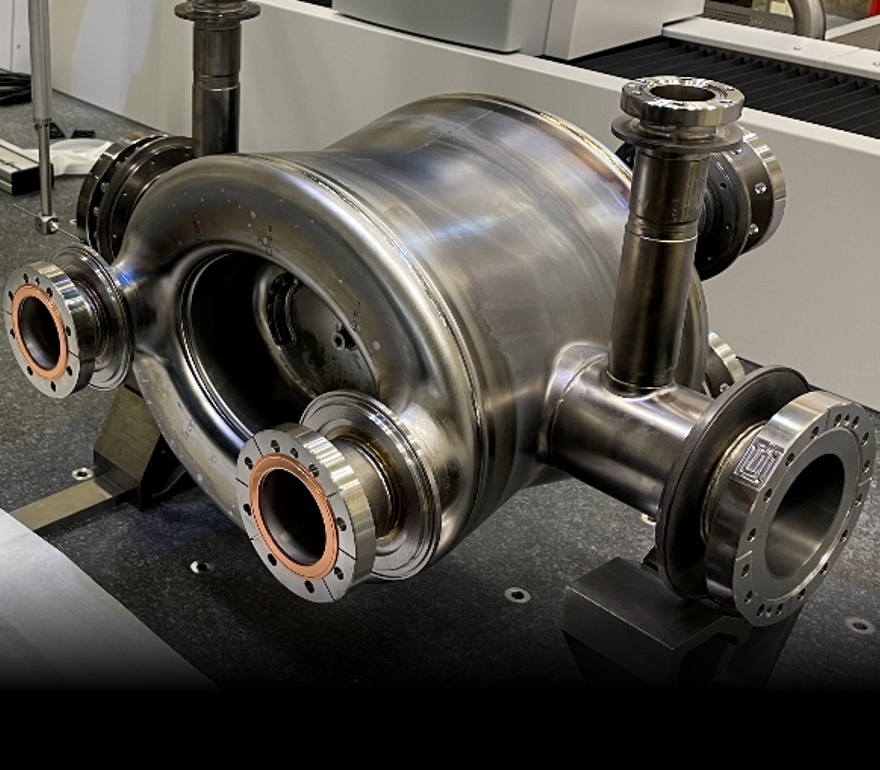

Our machining capabilities include multi-axis milling, turning, and EDM technologies, enabling the production of complex components with tolerances down to just a few microns and mirror-like surface finish. We work with a wide variety of materials, including exotic ones, and handle components across a broad range of sizes. To meet the specific requirements of each project, we also perform cryogenic machining, ultra-precision turning, and machining of radioactive components. We approach each project with adaptability and ingenuity, creating custom tooling and fixtures to achieve uncompromising results.

Milling

Our 5-axis CNC milling machines offer the accuracy and flexibility needed to manufacture complex geometries and high-end prototypes. We combine technical expertise, hands-on experience and targeted R&D to address the unique machining challenges of particle accelerator components, developing strategies that ensure precision, reliability and performance in every part we produce.

Turning

We provide precision turning on 2 to 4-axis CNC lathes capable of handling components up to 1000 mm in diameter and 2500 mm in length. In addition, we also operate CNC machining centers that combine turning and milling, allowing complex parts to be produced more efficiently and with higher accuracy.

Electrical discharge machining

We perform both wire and die-sinking EDM, enabling the production of thin-walled features, sharp internal corners, and tight-tolerance geometries in hard or delicate materials. Wire EDM achieves accuracies down to ±5 µm, while die-sinking enables production of intricate cavities. Equipped with a rotary axis, our wire EDM systems enhance our capability for machining complex geometries.

Specificities

We specialise in machining high-value components from exotic materials and radioactive materials, including parts for RF and SRF systems and multi-technology assemblies. By integrating advanced fabrication methods with strict quality control, we deliver reliable performance in the most demanding accelerator environments.

Capabilities

We machine components ranging from small parts just a few centimetres in size to large structures up to six metres in length. This versatility enables us to deliver both intricate prototypes and accelerator assemblies with the same uncompromising precision and quality.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the MME Machining Workshop can do for you.